OVERVIEW

The complexity and product variation of electrical distribution systems cannot be managed by human beings alone. Sophisticated software solutions are indispensable. Model based tools deliver substantial automation avoiding engineering errors & allowing engineers to innovate instead of performing mundane tasks, below we can see Capital PRODUCE tool suit and its 4 main products as Wire harness product & manufacturing engineering solutions:

- Capital Harness Designer Modular

- Capital Formboard Designer

- Capital Harness Process Designer

- Capital Work Instruction Publisher

Capabilities

Features That Make You Spellbound

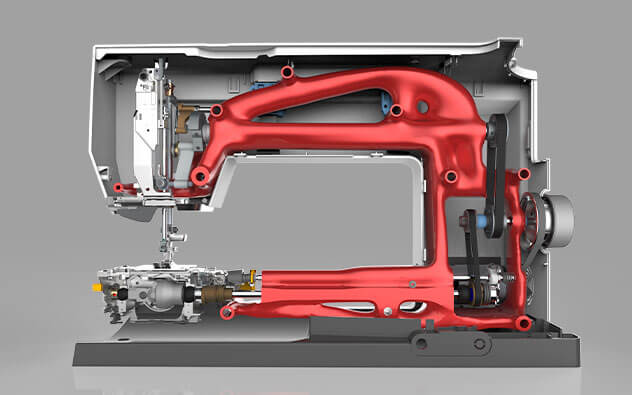

Capital Harness Designer Modular

It enables harness engineers to create fully detailed, validated, and manufacturing-ready harness designs from 150% harness designs. Buildable harness variants (including diagrams and BOMs) are automatically generated, based on user-defined choices for decomposition—Composite-Derivative or Modular decomposition.

Modular decomposition offers both functional module decomposition, for example “tail lamps,” and production module decomposition, for example “ECU connector sub-assembly.”

Multiple, configurable, design-rule checks are provided to ensure the final design meets the organization’s defined best-practices. Automated design comparison facilities identify graphical and specification changes between different revisions.

Capital Formboard Designer

Capital guides formboard designers to create an optimized, ergonomic layout based on dynamic feedback of labor effort/times related to each component, as it is placed in a particular zone on the board.

Designers can also create and maintain merged or combined formboards for efficient production lines and factory space usage.

Full-scale diagram capabilities linked to the baseline design enable changes made in the harness design to be automatically updated in the formboard diagram, eliminating a common source of error.

Capital facilitates the creation and maintenance of merged or combined formboards in an environment based on contiguous data flows.

Capital Harness Process Designer

It enables harness build procedures and activities, costs, manufacturing times, and more to be quickly and correctly synthesized by costing and process planning engineers from a harness design developed by Capital Harness Designer or Capital Harness Designer Modular.

Capital Harness Process Designer provides a formal framework and process for the rapid generation of accurate time and labor costing.

With functionality specifically created to assist the various engineering tasks: OEM cost controllers, OEM architects and designers, Supplier sales/quotation engineers, Supplier industrial engineers, and Supplier value engineers. Capital Harness Process Designer is intended to support both OEMs and Harness Suppliers.

Capital Work Instruction Publisher

As a final step, work instructions are created for operators on the assembly line. Given the complexity of today’s harnesses, instructions and visual aids must be generated automatically, and they must be explicit and error-free to ensure consistent, high-quality assemblies.

Capital Work Instruction Publisher enables documentation to be created directly from engineered harness data and the defined assembly process sequence.

Capital Workbooks uses rules to automatically generate work instructions and visual aids for harness assembly operators.

It removes work instructions creation from the critical path for introducing new or changed harness designs, thus eliminating errors, and reducing costs.