Overview

Digital manufacturing is an emerging area evolved from manufacturing initiatives such as design for manufacturability, computer integrated manufacturing, flexible manufacturing, lean manufacturing etc. The digital technology is breaching the walls of manufacturing due to the recent developments in areas such as human-machine interaction, automation, robotics and virtual commissioning. Before the actual production of the products start, we shall help you validate the manufacturing processes virtually. Digital simulation of the production cell, line or the entire plant is now possible to give optimized manufacturing processes, simulating the throughput and detailing such as material handling equipment and material movements.

Fields / Applications

Virtually commission your green field or brown field plants before investing.

Fixture/Tooling Design

Key Features

- Jigs, fixture design

- Sheet metal press tools design

- Plastic injection mold design

- Aluminium die casting dies design

- Special purpose machine design

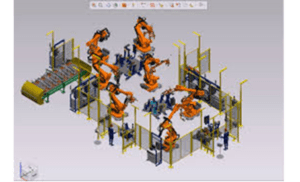

Robotic Simulation

Key Features

- Simulating multi-robot cells for material handling or welding processes

- Offline Programing of robots of various makes

- Optimization of robotic lines

Process Simulation

Key Features

- Optimize cycle times of discrete and continuous production lines through simulation

- Early validation of integrated mechanical and electrical systems

- Human, assembly, and robotic simulation

- Virtual commissioning of lines

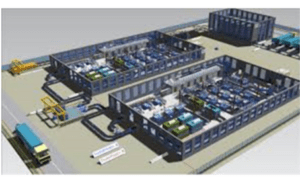

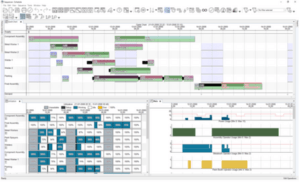

Plant Simulation

Key Features

- Simulate entire plan and validate and optimize throughput over a period

- Run ‘what-if’ scenarios before taking final layout decisions

- Eliminate bottlenecks, optimize energy usage

- Virtual commissioning of plants

Virtual Commissioning

Key Features

- Product digital twins

- Connection through TIA portal, PLC controllers

- Software in loop, Hardware in loop

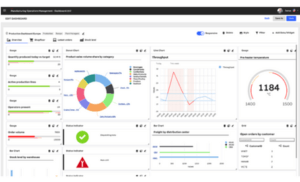

Manufacturing Operations Management (MoM)

Key Features

- Manufacturing Execution Systems (MES)

- Manufacturing Intelligence (MI)

- Planning and Scheduling

- Quality management

IoT/IIoT

Key Features

- Internet of Things / Industrial IoT

- Cloud based and On-premise options

- Integration with enterprise solutions