Dental 3D Printers

Transformational 3d Digital Dentistry Solutions Bring New Levels Of Clinical Performance, Workflow Efficiency And Workflow Automation

Overview

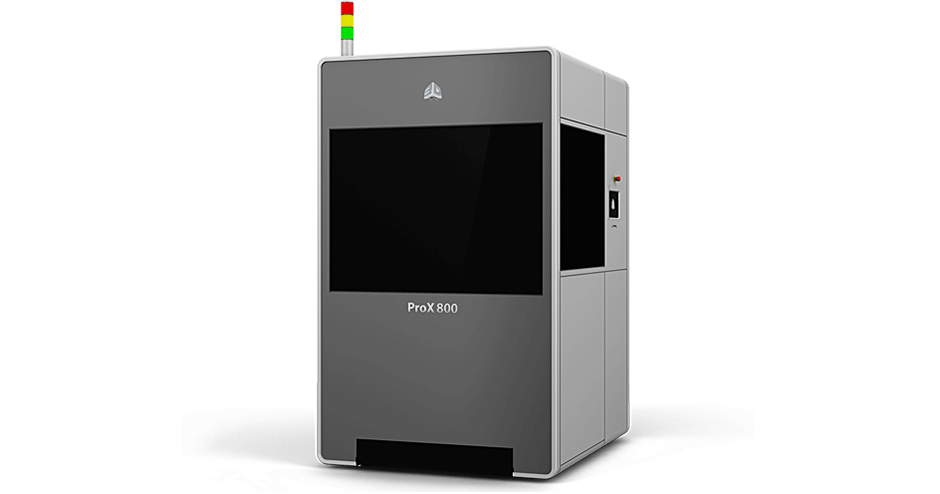

In the rapidly evolving business world, you need a 3D printer that puts you ahead of the competition.

3D Systems printers offer transformative advantages at every phase of creation – from initial concept design to the production of final products.

The most important step is to ensure you identify the best 3D printer technology for your application.

Dental Materials

Metal

High strength, low weight, excellent biocompatibility

High strength, low weight, excellent biocompatibility – lower Oxygen than Gr5

Light weight, biocompatible, extreme temperature and corrosion resistance

Highly corrosion and wear resistant, suitable for biomedical

NextDent

Highly accurate, high precision material for detailed master prosthodontic and orthodontic models

3D Print resin for the manufacturing of removable denture bases

3D Print resin for the manufacturing of castable parts

3D Print resin for the manufacturing of gingiva masks on dental models

3D Print resin for the manufacturing of individual impression trays

3D Print Resins for the manufacturing of prosthodontic and orthodontic models

3D Print resin for the manufacturing of dental splints

3D Print resin for the manufacturing of Indirect bonding trays.

Micro Filled Hybrid 3D print resin for the manufacturing of long-term temporaries

3D Print resin for the manufacturing of try-in devices

3D Print resin for the manufacturing of dental surgical guides

Plastic

Highly accurate, high precision material for detailed master prosthodontic and orthodontic models

3D Print resin for the manufacturing of removable denture bases

3D Print resin for the manufacturing of castable parts

3D Print resin for the manufacturing of gingiva masks on dental models

3D Print resin for the manufacturing of individual impression trays

3D Print Resins for the manufacturing of prosthodontic and orthodontic models

3D Print resin for the manufacturing of dental splints

3D Print resin for the manufacturing of Indirect bonding trays.

Micro Filled Hybrid 3D print resin for the manufacturing of long-term temporaries

3D Print resin for the manufacturing of try-in devices

3D Print resin for the manufacturing of dental surgical guides

High contrast, high modulus, heat resistant rigid tan plastic

High precision stone-like dental models

USP Class VI capable plastic, translucent

Solid stone appearance

Wax-up castable and pressable material

Accurate and durable dental model material