Overview

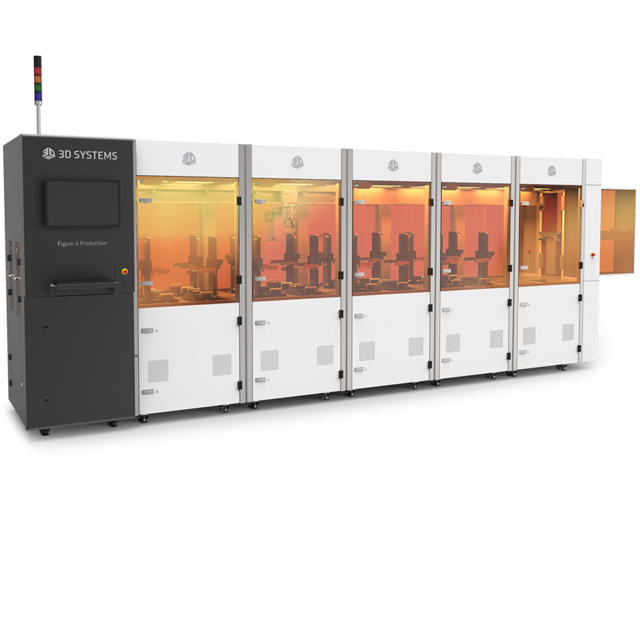

In the rapidly evolving business world, you need a 3D printer that puts you ahead of the competition.

3D Systems printers offer transformative advantages at every phase of creation – from initial concept design to the production of final products.

The most important step is to ensure you identify the best 3D printer technology for your application.

Materials

Making Product Sturdy

PA 2200 / 2201

Product Information

PA 2200 – Polyamide white The white powder PA 2200 on the basis of polyamide 12 serves a wide variety of applications with its very well-balanced property profile.

PA 2201- Polyamide natural PA 2201 is a white polyamide 12 powder for slightly more translucent parts. It is in compliance with FDA, 21 CFR, §177.1500 9(b) except for alcoholic foodstuff. Apart from that PA 2201 and PA 2200 have similar material properties.

Properties

- Multipurpose material

- Balanced property profile

- High strength and stiffness

- Good chemical resistance

- Excellent long-term constant behavior

- High selectivity and detail resolution

- Various finishing possibilities (e.g. metallisation, stove enamelling, vibratory grinding, tub coloring, bonding, powder coating, flocking)

- Biocompatible according to EN ISO 10993-1 and USP/level VI/121 °C

- Approved for food contact in compliance with the EU Plastics Directive 2002/72/EC (exception: high alcoholic foodstuff)

Applications

- Functional parts

- Medical applications, e.g. prostheses

- Fully functional plastic parts of highest quality

- Substitute typical injection moulding plastics

- Realisation of movable part connections

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

PA 2202 black – Parts with continuous coloring

PA 2202 black is a polyamide material with black pigments. The resulting parts are colored throughout their whole volume, which makes them resistant against scratches, abrasion, and dirt. The parts are thus very well suited for mechanically stressed applications or dirty environments. The polymer will be the first choice for industries where an anthracite black color of parts is relevant. This is, for example, the case for many components in the automotive industry, especially under-bonnet parts.

Properties

- Balanced property profile

- Anthracite black color

- Withstand high mechanical load

- High stiffness

- Excellent long-time stability

- Outstanding detail resolution

- Abrasion, scratches, later drillings without

- Discoloration

Applications

- Functional parts in anthracite black color

- Parts in design quality

- End products

- Spare parts

- Components with high soiling tendency

- Technical parts with requirements on optical effects

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

PA 1101

Product information

PA 1101 is a whitish-translucent polyamide 11 material, which is optimized for the use as a laser-sintering material. Laser-sintered parts made from PA 1101 are characterized by high impact resistance and elongation at break. The material is based on renewable resources and can, therefore, be classified as environmentally friendly material.

Properties

- High impact resistance & elongation at break with an otherwise balanced property profile

- Based on renewable resources

- Better temperature resistance than PA 12; nearly continuous mechanical properties at a wide temperature range

- No splintering and cracking, even under highest mechanical stress

Applications

The material is particularly suitable for applications with functional elements which require high material ductility (e.g. integral hinges) and ones where high impact resistance is important. Another typical application for this material is for components which do not allow splintering (e.g. parts to be used in the passenger compartment in vehicles).

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

PA 1102 black

Product information

PA 1102 black is a mass-colored black polyamide 11 powder, which is optimized for the use as a laser sintering material. PA 1102 black is made out of renewable raw materials (castor oil). The material is characterized by elasticity and high impact resistance.

Properties

- Mass-colored black

- High elongation at break

- High impact resistance

- Elasticity

- Excellent resistance to chemicals, especially hydrocarbons, aldehydes, ketones, mineral bases and salts, alcohols, fuels, detergents, oils and fats

Acceptance Criteria

- Cytotoxicity according to DIN EN ISO 10993-5

Applications

- Mechanically loaded functional prototypes and series parts with long-term moving elements (e.g. hinges)

in the automotive industry, it is mainly used for interior components for crash-relevant parts (PA 1101 components do not splinter) - Well suited for abrasively stressed visible parts

- Especially suited for small to medium sized parts, thin walls, and lattice structures.

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

PA 2210 FR - Flame-retarding Polyamide

Product information

PA 2210 FR is a white polyamide 12 powder with a halogen-free, chemical flame retardant. In case of a fire a carbonating coating arises on the surface of the part, isolating the plastic below. PA 2210 FR fulfils the flame protection classification UL 94 / V-0 from a wall thickness higher than or equal to 2 mm.

Properties

- Flame retardancy

- Halogen-free

- Good mechanical properties

- Excellent long-term constant behavior

Applications

- Aerospace

- Electric & electronics

- Fully functional, load-bearing plastic parts of the highest quality

- Parts with increased requirements on flame protection

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

PrimePart FR (PA 2241 FR) - Flame Retardant Polyamide

Product information

PA 2241 FR is a flame retardant polyamide 12 for processing in laser sintering systems. It contains a halogen-based flame retardant. Mainly due to the recyclability the material is economical, enabling low-cost part production. The flame-retardant material is suitable especially for application in the aviation sector. Typical applications in aircraft interiors include air ducts and outlet valves.

Properties

- Flame retardancy

- Economic

- High strain at a tensile strength

Applications

- Aviation (interior, e.g. air ducts and air outlet valves, acceptance criteria: JAR 25)

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

PA 3200 GF - Glass bead filled polyamide

Product information

PA 3200 GF is a white, glass bead filled polyamide 12 powder, which is characterized by an excellent stiffness in combination with good elongation at break.

Properties

- High stiffness

- Wear resistance

- Improved temperature performance

- Good thermal loadability

- Excellent surface quality

- High dimensional accuracy and detail resolution

- Good processability

Applications

- Stiff housings

- Parts with requirements on wear and abrasion

- Parts used under elevated thermal conditions

- Usage e.g. for final parts within the engine area of cars

- Deep-drawing dies

- Any other application which requires particular stiffness, high heat distortion temperature, and low abrasive wear

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

EOS PEEK HP3 - Polyaryletherketone

Product information

EOS provides the world-first high-performance polymer for the laser-sintering process – EOS PEEK HP3. Belonging to the group of Polyaryletherketone (PAEK), this semi-crystalline, thermoplastic material was developed for the use on the high-temperature system EOSINT P 800.

The laser-sintered parts achieve a tensile strength up to 95 MPa and Young’s modulus up to 4400 MPa. These values are on an up to 100 percent higher level than the so far market dominating materials PA 12 and PA 11. The continuous use temperature ranges within 180 °C (mechanical dynamic), 240 °C (mechanical static) and 260 °C (electrical) depending on the field of application which could not be reached so far.

Properties

- High-performance material

- Excellent temperature performance, strength, stiffness and Chemical resistance

- Best fire, smoke and toxicity performance

- Excellent wear resistance

- Inherently flame retardant

- Sterilisability

- Excellent high-temperature performance

- Good hydrolysis resistance

Applications

- Metal replacement

- Aerospace

- Automotive and motorsports

- Electric & Electronic

- Medical- ideal replacement for stainless steel and titanium

- Industrial

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

EOS PP1101 - Polypropylen (unfilled)

Product information

EOS PP 1101 is a natural-white, unfilled polypropylen powder for various applications. Built parts feature good flexibilty, stiffness as well as high chemical resistance. The used powder is fully recyclable, which makes the material ideal for the economic production of functional parts.

Properties

- Excellent resistance to chemicals, especially hydrocarbons, aldehydes, ketones, salts, oils, and fats as well as acids

- Good elongation at break

- High impact strength

- Attractive cost per part due to a recycling rate of 100%

Applications

- Pipes, mixers and chemical reactors

- Parts exposed to high chemical stress

- Housings

- Gripper

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

Alumide® - Polyamide aluminium-filled

Product information

Alumide is a metallic grey, aluminum-filled polyamide 12 powder, which is characterized by its high stiffness, metallic appearance, and good postprocessing possibilities. The surfaces of Alumide parts can be refined very easily by grinding, polishing or coating. The machining of Alumide laser-sintered parts is simplified through the cut breaking effect of the aluminum filling.

Properties

- Easy post-processing, good machinability

- High-temperature performance

- Thermal conductivity (limited)

- High stiffness

- Well-balanced ratio of density and stiffness

- Excellent dimensional accuracy

Applications

- Applications with the metal-like look

- Parts which need machining

- Parts with thermal loads

- Manufacture of stiff parts of metallic appearance for applications in automotive manufacture (e.g. wind tunnel tests or parts that are not safety-relevant)

- Tool inserts for injecting and moulding small production runs

- Illustrative models (metallic appearance)

- Setting jig and device manufacture

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

CarbonMide® - Polyamide carbon fiber-reinforced

Product information

The anthracite black, carbon-fiber reinforced polyamide 12 material stands out for excellent stiffness and a maximized weight-strength-ratio. Due to the process related orientation of the fibers the mechanical properties varies in the three axis directions.

Properties

- Extreme strength and stiffness

- Thermal and electrical conductivity (limited)

- Best strength/weight-ratio

- Light weight

Applications

- Light and stiff functional parts

- Metal replacement

- Mechanically stressed parts which are optimized considering the self-weight of the part

- Aerodynamic components in motor sports application

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

PrimeCast® 101 - Polystyrene

Product information

PrimeCast 101, a grey powder on polystyrene basis, is suited especially for investment casting due to its excellent dimensional accuracy and its low melting point.

Properties

- High dimensional accuracy

- Low residual ash-content

- Very high surface quality

- Good strength for use as lost pattern

Applications

- Patterns for investment casting

- Master patterns for vacuum casting, herby it is advised to infiltrate the parts with e.g. epoxy resin

- Production of lost patterns for the plaster and ceramic shell casting process.

The material is optimized for minimum residue ash content after burning-out.

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.

PrimePart PLUS (PA 2221)

Product information

PrimePart PLUS (PA 2221) is a polyamide 12 powder optimized for low warpage and lowest refresh rate. Therefore the need for new powder is diminished, making PrimePart PLUS a highly economical and ecological material. PrimePart PLUS is in compliance with FDA, 21 CFR, §177.1500 9(b) except contact with alcoholic foodstuff. Laser-sintered parts from PrimePart PLUS are natural colored. They possess excellent material properties:

Properties

- Economic multipurpose material

- Balanced property profile

- Variety of certificates available (biocompatibility, food contact)

- High strength and stiffness

- Good chemical resistance

- Excellent and constant long-term behavior

- High accuracy and detail resolution

- Various finishing possibilities (e.g. metallisation, stove enamelling, vibratory grinding, tub coloring, bonding, powder coating, flocking)

Applications

Typical applications for parts produced with this material are fully functional parts of the highest quality. Due to the excellent mechanical properties, PrimePart PLUS is often used as a substitute for typical injection moulding plastics.

PrimePart® ST (PEBA 2301)

Product information

PrimePart® ST (PEBA 2301) is a natural colored powder of a polyether amide, which is developed and optimized for the application in a Laser Sinter system. Laser-sintered parts made from PrimePart® ST (PEBA 2301) possess excellent material properties:

Properties

- High elasticity and strength

- Good chemical resistance

- Excellent long-term stability

- High selectivity and detail resolution

- Various finishing possibilities (e.g vibratory grinding, flame treatment, tub coloring, bonding, flocking)

Applications

Typical applications of the material are fully functional, flexible plastic parts of the highest quality. Due to the excellent mechanical properties, the material is often used as a production material for long term use. The rubber-like fatigue behavior qualifies Prime Part® ST (PEBA 2301) as excellent prototyping and series material.

Technical information, material data sheets for materials made of plastic and information about standardized material properties, Part Property Profiles, please refer to our materialdatacenter.