Overview

In the rapidly evolving business world, you need a 3D printer that puts you ahead of the competition. Intech Additive printers offer transformative advantages at every phase of creation – from initial concept design to the production of final products. The most important step is to ensure you identify the best 3D printer technology for your application.

Applications

iFusion SF1

Aerospace Industry

In the Aerospace sector, additive manufacturing is often used for producing light weight, strong aerospace parts like fuel nozzles and turbine blades.

Automotive Industry

It combines additive manufacturing and simulation to create prototypes that can be tested for form, fit and performance. Parts like intake manifold, fuel pumps, flow control valves, lamp parts, and mirror moulds are developed using additive manufacturing.

Dental Industry

It employs additive manufacturing for producing customised crowns, bridge implants, and complete/partial dentures made to patient-specific requirements. It enables generation of precise and smooth surfaces with minimal post-processing.

Medical & Healthcare Industry

The orthopaedics and medical industry demand high-precision, perfectly fitting, patient-specific customized implants like Implants for joints (Titanium cups for hip and knee implants), Cranio-Maxillofacial implants, Implantable heart valves and Rib cages.

Academic, Universities and R&D institutes

The iFusion SF1 is a perfect fit for Universities and R & D institutes carrying out instruction and research in rapid prototyping and additive manufacturing. SF1’s optional AMOptoMet opens up print parameter generation by allowing new parameters to be developed to print with customized alloys or develop new ones.

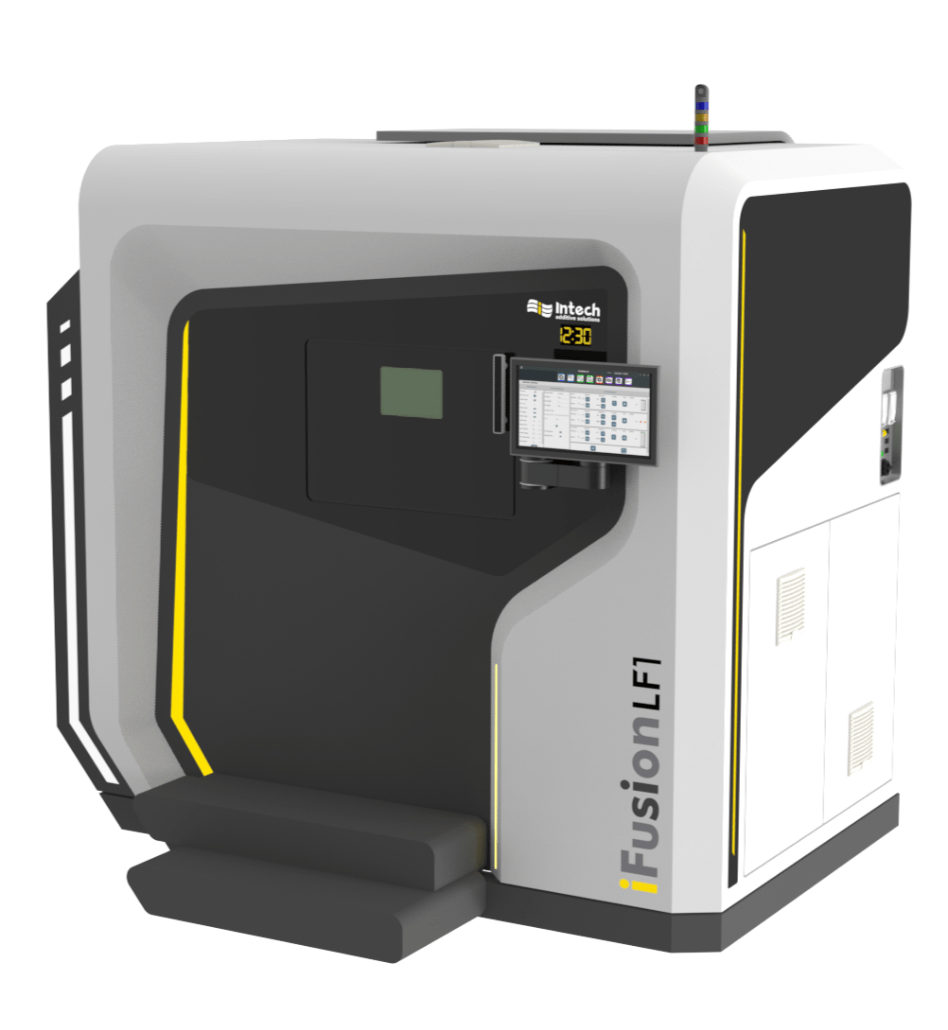

iFusion LF

Aerospace Industry

Additive manufacturing enables the production of parts which are of lower weight, complex geometric designs, while meeting the same strength requirements as parts manufactured by conventional means. Additive manufacturing enables the production of parts which are of lower weight, complex geometric designs, while meeting the same strength requirements as parts manufactured by conventional means.

Automotive Industry

It combines additive manufacturing and simulation to create prototypes that can be tested for form, fit and performance. Parts like intake manifold, fuel pumps, flow control valves, lamp parts, and mirror moulds are developed using additive manufacturing. This results in lower initial investment, shortens the development phase of the product life cycle, and enables a faster time-to-market for new models.

Tool and Die

While once the industry was restricted by limitations like simple cooling solutions by drilling in straight lines, Additive Manufacturing now enables Conformal Cooling Solutions where complex free-form internal channels to provide optimum cooling and tempering solutions. This offers various benefits like minimal war page and reduced cycle time, and hence, results in better quality parts produced in a shorter time.

General Engineering

Additive Manufacturing provides industrial companies with completely new solutions for realizing tool-less production methods. The technology gives designers maximum freedom of design. Providing material only where it is needed for mechanical strength or functionality, this solution can also manufacture lightweight parts with highly complex geometries. Equipped with tools to transform design based on functionality, Additive Manufacturing has already set on the path to transform the entire General Engineering Industry.

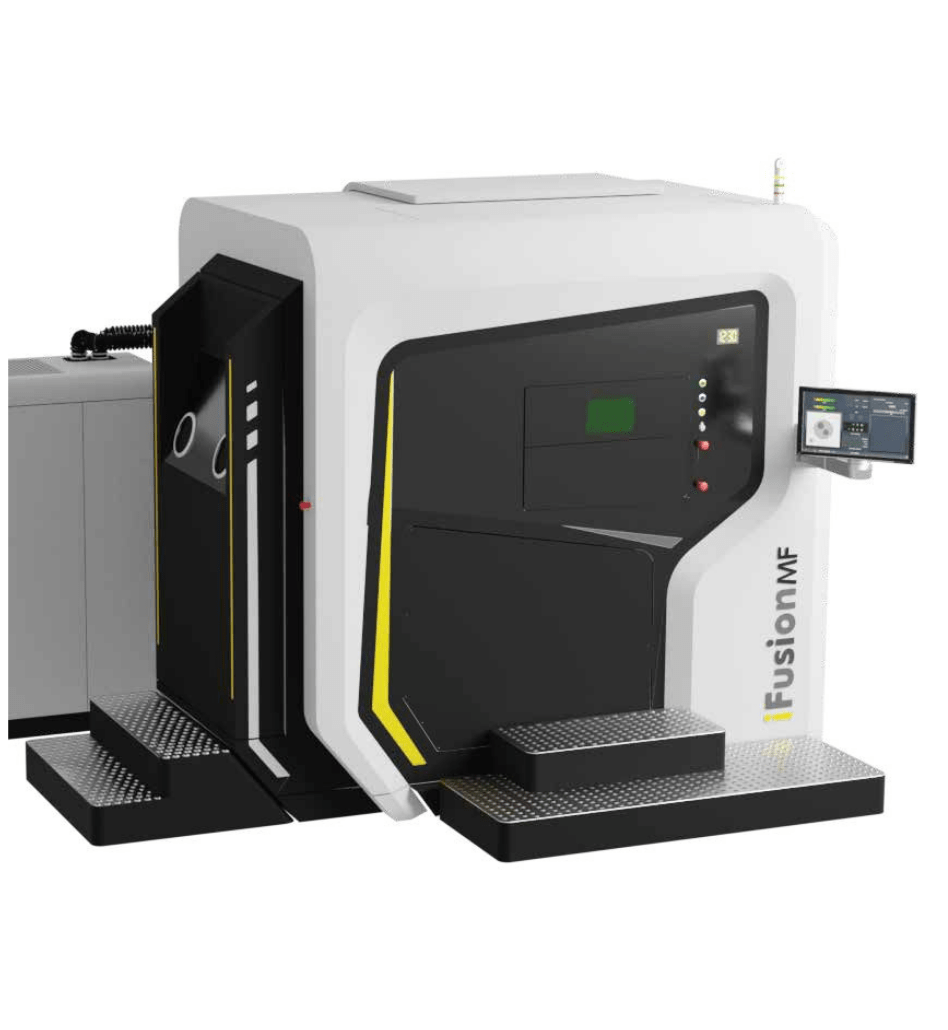

iFusion MF

Aerospace Industry

Additive manufacturing enables the production of parts which are of lower weight, complex geometric designs, while meeting the same strength requirements as parts manufactured by conventional means. Additive manufacturing enables the production of parts which are of lower weight, complex geometric designs, while meeting the same strength requirements as parts manufactured by conventional means.

Automotive Industry

It combines additive manufacturing and simulation to create prototypes that can be tested for form, fit and performance. Parts like intake manifold, fuel pumps, flow control valves, lamp parts, and mirror moulds are developed using additive manufacturing. This results in lower initial investment, shortens the development phase of the product life cycle, and enables a faster time-to-market for new models.

Tool and Die

While once the industry was restricted by limitations like simple cooling solutions by drilling in straight lines, Additive Manufacturing now enables Conformal Cooling Solutions where complex free-form internal channels to provide optimum cooling and tempering solutions. This offers various benefits like minimal war page and reduced cycle time, and hence, results in better quality parts produced in a shorter time.

General Engineering

Additive Manufacturing provides industrial companies with completely new solutions for realizing tool-less production methods. The technology gives designers maximum freedom of design. Providing material only where it is needed for mechanical strength or functionality, this solution can also manufacture lightweight parts with highly complex geometries. Equipped with tools to transform design based on functionality, Additive Manufacturing has already set on the path to transform the entire General Engineering Industry.

Dental & Medical

It employs additive manufacturing for producing customised crowns, bridge implants, and complete/partial dentures made to patient-specific requirements. It enables generation of precise and smooth surfaces with minimal post-processing.

Research & Development

The iFusion MF is a perfect fit for R & D institutes carrying out instruction and research in rapid prototyping and additive manufacturing. SF1’s optional AMOptoMet opens up print parameter generation by allowing new parameters to be developed to print with customized alloys or develop new ones.

Education

The iFusion MF is a perfect fit for Universities carrying out instruction and research in rapid prototyping and additive manufacturing. SF1’s optional AMOptoMet opens up print parameter generation by allowing new parameters to be developed to print with customized alloys or develop new ones.